Garford Farm Machinery returns to Lamma with three new developments in its precision weeding portfolio.

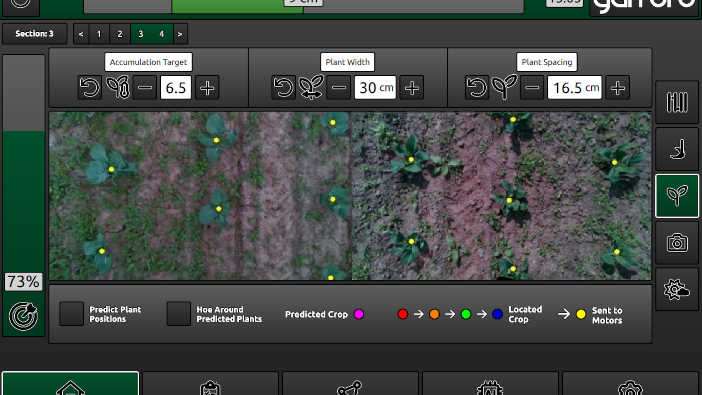

Initially shown at the World Agri Tech Innovation Summit in September, Lamma will be the first opportunity for many to see the Robocrop AI system.

Developed in-house, the vision guidance system uses AI to monitor colour, infrared and depth information to locate crop, plant and stem location, making it capable of precise weeding in a green-on-green environment.

“In practice, this means we can hoe closer to the plant to achieve a higher weed control efficacy, ultimately bringing value to the user,” explains Garford Farm Machinery managing director Jonathan Henry.

The company adds that the system is resistant to varying light conditions, and can work in fields with varying weed pressures.

It’s available for the 2025 model InRow electric rotor weeders for use in salad, brassica and sugar beet crops.

Electric weeding

Electric weeding

There will also be opportunities to see developments following Garford’s partnership with RootWave. The RootWave system uses electricity to boil weeds and the roots, without the need for chemicals.

This not only represents a potential financial gain for the user but also means that the system can be used within organic and regenerative systems.

“Combining our technologically advanced precision-guided weed control solutions, with the benefits of RootWave’s high frequency alternating current electrical weeding technology, we can create commercially viable and effective solutions to growers, as a key part of a sustainable, integrated weed management system,” adds Jonathan.

Flexible hooded sprayer

Flexible hooded sprayer

Finally, the company will showcase a new flexible hooded sprayer concept, Flexi Hood, which uses floating side shields to allow for narrower passes and greater clearance between the hoods for the crop to move through.

“This makes it an attractive proposition for a number of crop applications, from saplings and root crops to fresh produce, salads and herbs and even bulbs,” explains Allan Knight, Garford Farm Machinery’s technical sales and marketing manager.

The floating hoods follow the contours of the ground, while the fabric bellows flex to the movement to maintain a seal.

“This has enabled us to reduce crop clearance by half, from 200mm to 100mm, and the Flexi Hood can also be used in raised bed or flat-bed situations,” explains Allan.

For more information go to www.garford.com