Yorkshire-based manufacturer, Kentra, has introduced two new moisture measurement and recording systems for growers, and an automated installation for mills and commercial grain stores. These high-accuracy products are imported from Canadian company Dryer Master, which previously developed the DM510 control system for full automation of the grain drying process.

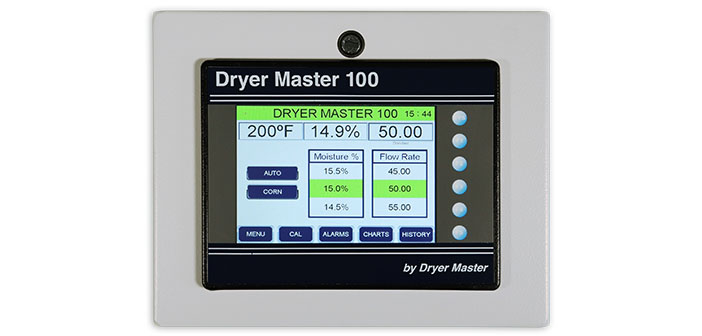

The new DM100 system is a lower cost, less sophisticated version while still providing an element of control to ease the operator’s workload. Grain moisture is measured at the discharge point and adjustments to the discharge rate made automatically when operator-set targets for moisture levels are hit. Unlike the flagship DM510, the speed set points and moisture targets need to be adjusted periodically to maintain performance.

Using the latest Moisture Monitor Pro, grain moisture and temperature is recorded at the discharge, with the option to add an intake sensor as well. This is designed to help operators achieve consistent results from fully manual control. Like the fully automatic and semi-automatic systems, values are shown on a colour display and can be remotely accessed using a mobile phone and downloaded to PC for record keeping.

These features are also integrated into the new Load Monitor, designed to be used with batch dryers or to record the average moisture of entire lorry or trailer loads of grain at the intake of feed or flour mills or commercial grain stores. A sensor is fitted in the grain flow line and automatically begins recording data when the sensor detects grain flowing over.

The finished record includes a consignment identifier and time stamp, and compared with sampling, eliminates delays for incoming consignments and provides a reading that is representative of the bulk.