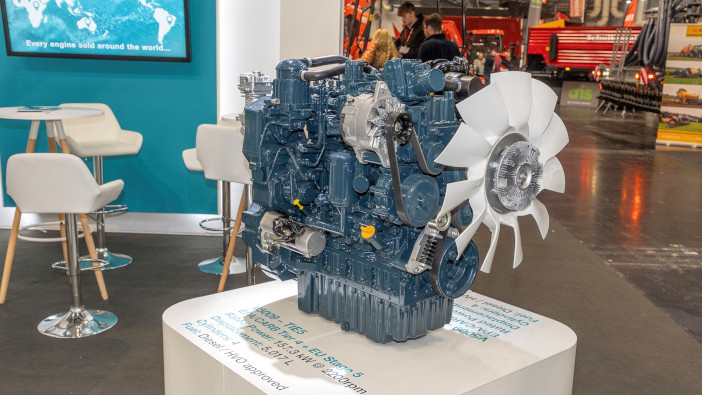

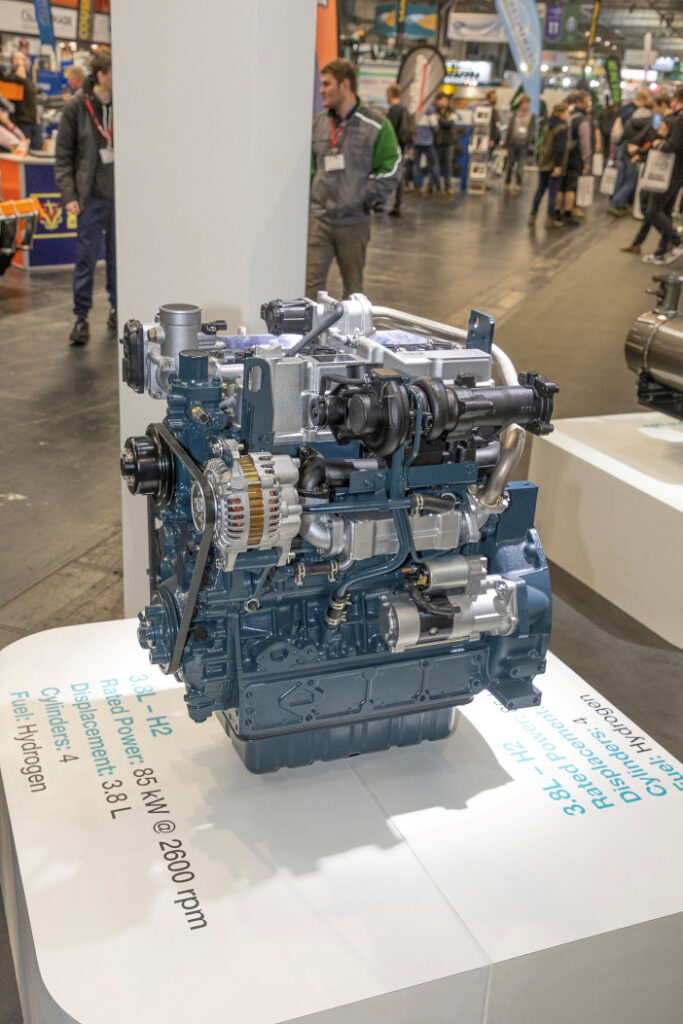

At Lamma 2024, Kubota introduced a series of new engine technologies designed for the OEM market. These included a 3.8-litre hydrogen engine, as well as the company’s most powerful unit to date.

The H2 hydrogen power unit is based on the spark ignition, four-cylinder WG3800 engine, delivering a rated power of 114hp at 2,600rpm. Eliminating carbon dioxide emissions, it has already garnered interest from the wider industry, with a mobile generator manufacturer agreeing on a deal with Kubota to produce a dedicated hydrogen generator with the unit.

The V5009 pushes Kubota past the 200hp barrier, producing 210hp at 2,200rpm while retaining the four-cylinder design. It features a 100% power take-off at the flywheel and front end, with a side power take-off with up to four hydraulic pumps and a choice of flywheel and flywheel housing.

It also features a direct injection combustion system and common rail fuel system, with a high-pressure supply pump, an optimised water jacket with heat resistance and a ladder frame structure to reduce noise. According to the company, fuel consumption has been reduced thanks to increased cylinder pressure and the engine has been designed to have a cold-start capability.

Daniel Grant, manager of marketing intelligence for Kubota Business Unit Engines Europe, said: “These latest engines underpin our determination to provide innovative solutions for the farming sector and this demonstrates our commitment to the wider environment through the use of carbon alternative fuels. Because our new engines have the same footprint as existing models, the demands placed on maintenance and installation teams are greatly reduced. And with our engines being so compact we can offer enhanced power from the same machinery dimensions.”

For more information go to www.kubota-eu.com