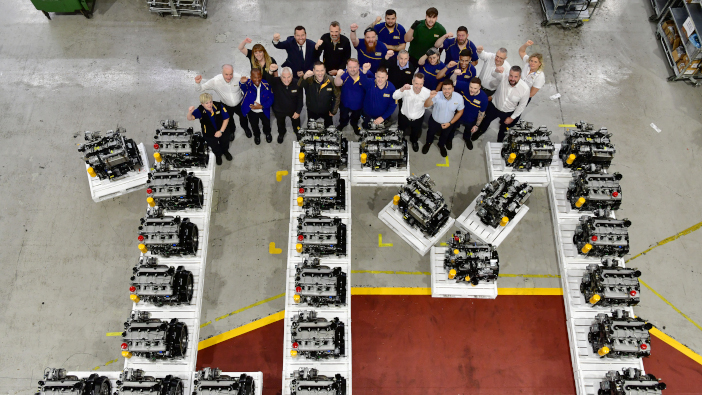

JCB has hit a major production milestone, with its one-millionth engine leaving the production line.

The company started building its engines in 2004 at JCB Power Systems in Foston, Derbyshire, before expanding production to JCB India in 2010, with a dedicated factory in Ballabgarh, Delhi.

Initial production topped out at three engines per day, now the company produces around 500 a day and has pushed development to include its hydrogen combustion engines.

JCB Chairman Anthony Bamford paid tribute to the JCB teams around the world who have played a part in the engine’s success: “To have made one million engines in 20 years is quite some achievement. This really is a significant moment for our teams around the world, a real achievement.

“The JCB engine is very well respected around the world for its reliability and very well appreciated by our customers. JCB machines work in dirt and hot and cold climates, and from the moment they go to a customer, they are working hard and doing a full day’s shift. The engine really is the beating heart of that reputation for reliability.”

Continuing, Lord Bamford said: “It was a major decision at the time to make our own engines and I was directly involved in that; it has paid off and I’m very pleased we made the decision. As we hit the milestone of producing one million engines, the time is right to acknowledge the part my played father in the design, not only of this engine, but other engines which he designed with other people in the past.

“My father died in 2001 so our engines were running as prototypes by that time, and he had a lot to do with it. I’m thankful he was involved in this engine so many years ago.”

Engines from JCB Power Systems have not only powered agricultural and construction equipment, but they have also played a role in setting world records. These include the JCB Dieselmax streamliner, powered by two engines, which became the fastest diesel-powered car in 2006, reaching 350.092mph.

In 2019, the company also set the record for the world’s fastest tractor, reaching 135.191mph in a heavily modified Fastrac, powered by a 7.2 litre, 6-cylinder Dieselmax engine.

Now, more than 150 engineers are engaged in the development of hydrogen engines as part of a £100 million investment, with more than 120 units produced already.

For more information go to www.jcb.com