Vegetable handling solutions manufacturer Haith is set to unveil its latest mobile machinery innovation, a Mobile Water Treatment System, at Interpom 2022; taking place from Sunday, November 27 until Tuesday, November 29, at the Kortrijk Xpo Centre in Belgium.

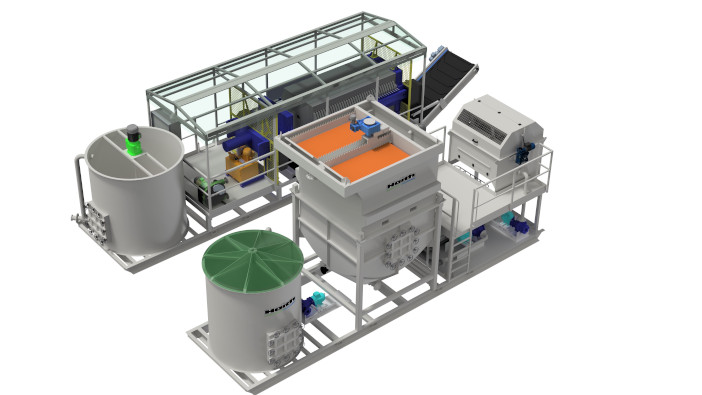

With Haith’s new modular system, the plant splits in two units for easy transportation by low loaders without special permits. It can also be assembled in less than two days using forklifts.

As such, the system can be used on-farm in strategic locations, or at production factories, and is more easily exportable to European companies. Haith had previously withheld from exporting systems because of complicated planning processes and transportation costs.

How it works

Once connected to a washer, dirty water flows into the Mobile Water Treatment System, where a screen initially separates larger organic matter from the water. The effluent is then pumped to a lamella settler which separates the soil from the water. The sludge then drops to the bottom of the tank and is pumped to a dewatering filter press on the opposite side of the unit.

The resulting soil cake can then be moved into a skip or presented to an elevator for emptying into a bucket on a teleporter before being returned to the field. Clean water is gravity fed into a storage tank for returning to the process or being allowed to discharge.

Duane Hill, Haith managing director, said of the innovation: “Permanent water treatment and recycling systems are really in demand at the moment as they significantly reduce water consumption by up to 90%, and provide fresh recycled water to the washing process. But this can be a considerable investment for a full scale installation.

“Having received several enquiries from potential customers overseas and having enjoyed considerable interest in our new mobile optical sorter, we decided to develop a mobile solution. We are confident that our new Mobile Water Treatment System will be very popular in the UK and further afield.”