With more products coming onto the market, grass mergers are clearly an area of interest for both manufacturers and customers.

A reduction in crop contamination, less likelihood of stones and soil being picked up and lower crop losses have all contributed to the rising popularity of grass mergers as an alternative to rakes. With the major difference being the grass mergers’ ability to lift the crop onto a belt conveyor before the swath is deposited so that grass isn’t dragged along the ground.

Manufacturers report that demand is high and those interested are looking for either a reduction in the number of stones going into a swath, or they are looking to feed an AD plant, where high levels of soil, ash and stones can cause issues.

Grass mergers particularly suit stony conditions, and the gentle action is effective on delicate crops. The lifting action of the machine, as opposed to the sweeping movement of a rake, leads to less stripping and reduced damage. There is less likelihood of stones and soil being picked up by a merger, which saves blades and chutes on harvesting kit.

There are a range of options, varying in size, application and attachment and it is important to consider the needs of individual users, but the cleaner grass gathering and higher work rates makes grass mergers an efficient and effective option for farming a variety of crops and ground conditions.

Kuhn – www.kuhn.co.uk

Kuhn’s Merge Maxx is available in working widths from 5.5 to 11 metres and includes the 760, 960 and 1090 models. All use two adjustable, variable width and bi-directional belts that provide multiple swath delivery options. Pick-up and swath width can be adjusted to suit the user’s needs.

For lateral swaths, the width can be varied between 1 and 1.50m. For central swaths, the width can be set to a maximum of 2.2m. Clean grass pick-up and the ability to produce a swath which is free of stones, soil or other impurities is controlled by design features including articulated pick-up skids, powerful lift-control springs, and pivot points which result in 26% less ground pressure than the equivalent of one person weighing 90kg. Less debris within the swath benefits animal health and translates to less time and money spent on replacing blades and other wearing parts on the baler.

The Merge Maxx belt merger can operate in a variety of forage types, and preserves nutritional value of the crop. Compared to a conventional grass rake, the Merge Maxx offers an increase in working rate, with the greatest time savings to be made when handling wet or heavier forage crops.

Read about Kuhn’s trailed sprayer here

Kverneland – uk.kverneland.com

The full range of ROC mergers are available to Kverneland and all models use a pick-up with six tine bars, with tines running between quiet plastic guides that lift the crop onto a one-metre deep belt. Forage can be moved left, right or to the centre. A self-contained hydraulic system eases the pressure on tractor power and along with four support wheels under each bed there is a rocking beam for contour following. Other features include auto-greasing and manual/auto start/stop of beds.

New models were launched in 2022, including the front-mounted RT380, which can be fastened to the front or back of the tractor. The continuous merger RT 730 has a variable working width from 5.95-7.30m with a double hydraulic rocker arm system that allows the user to change the distance between the two pick-ups.

The ROC RT 1220 is reportedly the largest merger in the world and, while being too large for use on British public roads, it is an alternative option for ring-fenced holdings.

Pottinger – www.pottinger.uk

Winner of Farm Machine 2023 in the forage harvesting category at the SIMA awards in November 2022, Pottinger’s new Mergento VT 9220 merger boasts working widths of up to 9.20 metres for a central swath and 8.70m for a side-swath. Designed to work with a variety of crops, it utilises a six-row controlled pick-up to collect the crop, leaving dirt and stones on the ground, then a cross conveyor belt to deliver the forage to the swath. The chassis rollers are positioned close to the point the tines contact the crop to ensure optimum ground tracking and the boom’s three hydraulic cylinders react quickly to any bumps.

In the centre-swath mode, the vertical freedom of movement is +475 to -195mm while lateral float is +30ᵒ to -13ᵒ. The inclination in the direction of travel can move from +11.5 to 0ᵒ. Controls in the tractor cab allow for adjustments to be made in the direction of rotation and the position of the two cross-conveyor belts.

The new machine can place a centre swath, swaths to the left or right, two single swaths, convey from the inside out and load forage for a short period. Combining versatility and reliability when raking any type of crop, this model is a real all-rounder. Demonstrations of this new model will take place in the 2023 grass season.

Read about Pottinger’s factory expansion here

Respiro – www.reiter-respiro.com

Respiro’s biggest seller is its trailed machine – the R9 Profi. With high flexibility, users can create the swath size most suited to their needs and options of side, centre, single night, and half side swaths are available. Its robust design with a four-wheel chassis allows for effective ground hugging and less forage contamination while its high working speed leads to efficient performance. The reduced ground pressure with this machine makes it suitable for use in wet conditions.

Also available is the R6/7 rd, which is a cost-effective alternative to the trailed machines. Offering side and half side swaths, it boasts patented suspension using four spiral springs meaning there is less weight on the ground and less wear on the machine. The smallest model is the R3/3.5; a pushed machine which works with smaller tractors. Benefits include easy lifting, fast reaction speeds and easy operation.

All Respiro models offer the same technology in terms of a flexible pick-up, small diameter, trailing times and a cam-less pick-up. Anti-loss systems are in place to ensure the tine coil is supported from the inside and the merger has an efficient working time.

SIP – www.sip.si

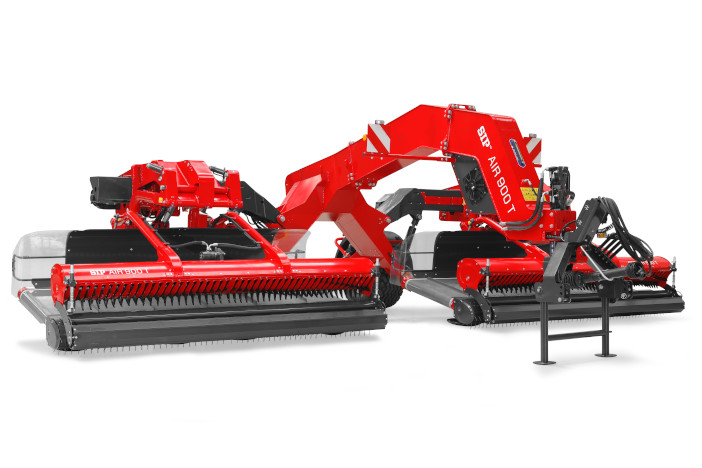

SIP presents the trailed pick-up rake AIR 900 T. The combination of a patented flexible pick-up unit, rotor accelerator and conveyor belt enables the formation of airy and evenly distributed swaths. The rake is designed to prevent the loss of sensitive leaves and the introduction of soil and sand into the swaths, ensuring the harvesting of high-quality forage.

The design gives a raking – working width of nine metres for central and 7m for side swath delivery and high clearance between the frame and the ground results in evenly shaped swaths. The model ensures even operation of the pick-up system on more demanding terrains, where it is necessary to increase the tractor engine speed and the output shaft. A belt drive with hydraulic motor allows speed and rotation direction to be set using the control unit.

The segmented central axis allows the flexibility of the pick-up unit and enables adaptation as it follows the ground along a curved line. This allows harvesting without damaging the turf and no forage residues in the field.

A combination of a small diameter pick-up rotor, finger rotor, and front roller on the pick-up unit ensures a smooth flow without turbulence and accumulation of forage in front of the rake and prevents leaf losses, especially in legume forages. With the capacity of the AIR 900 T of up to 15 ha/h the machine is designed for professional agricultural producers and contractors.