Following recent acquisitions and investments, Cummins has focused on three key areas for hydrogen combustion engines: the production of green hydrogen, the management and transportation of hydrogen, and the application of hydrogen in engines and fuel cells.

“Cummins has developed leading power solutions for over a hundred years, and we continue to demonstrate our leadership in developing a broad range of sustainable drivetrains looking to the future – with hydrogen playing a key role,” said Antonio Leitao, Cummins VP Off-Highway Engine Business. “Our strategy is to focus on the complete hydrogen value chain to drive sustainability and enable faster adoption.”

Green hydrogen, which reportedly produces zero greenhouse gases, is produced using electrolysis to turn renewable energy into hydrogen. This uses an electrolyser and the company is establishing new plants in La Mancha, Spain and Minnesota, USA as well as expanding production at Oevel, Belgium and Mississauga, Canada.

On-board storage remains a critical part of the hydrogen roll out and the company has a joint venture with NPROXX – a specialist in high-pressure hydrogen storage – to support OEM integration. The new tanks will have up to 700-bar of pressure to maximise capacity and operating range.

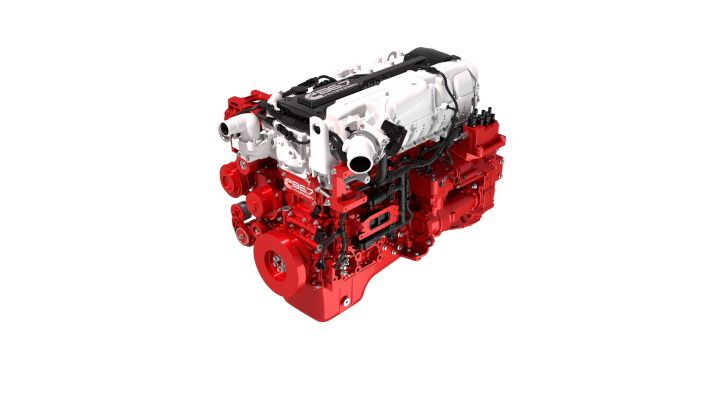

Finally, the company is producing hydrogen combustion engines, with the new B6.7H engine being shown at Agritechnica, which is suitable for agricultural applications. It offers up to 290hp and a peak torque of 1,200Nm, and can be mounted conventionally, with only the head and the fuel system changing.

“A hydrogen combustion engine fits in today’s machines, works with today’s transmissions, and integrates seamlessly into the industry’s existing service networks and practices,” added Leitao.

For more information go to www.cummins.com