The hydraulically operated three-point linkage developed by Harry Ferguson was one of the most important advances in power farming history, and it made its first appearance on the Black Tractor.

Harry Ferguson began developing the ideas that produced his implement attachment and control system during the 1914-18 war while he was running his car sales and servicing business in Belfast, in what is now Northern Ireland.

He had started the business because of his interest in anything mechanical, and it provided a welcome alternative to his childhood on the Ferguson family farm where he and his brothers were expected to help, but Harry disliked the slow pace of working with horses.

War effort

His interest in tractors started during the urgent wartime campaign to boost food production in Britain.

Large numbers of men and horses were leaving the farms to travel to the battlefields of Europe, reducing food production at a time when German U-boats were destroying many of the ships bringing imported food supplies.

There was a real risk that lack of food might force Britain to surrender, and the government’s response was a big increase in tractor power to boost productivity.

The food production campaign prompted Ferguson to add tractors to his car business, selling the Waterloo Boy tractor imported from America.

With his farming background and his mechanical skills, Ferguson took a close interest in his new tractor business, organising many of the demonstrations.

His operating skills attracted official recognition and in 1917 the Board of Agriculture asked him to tour farms in Ireland that used a tractor so that he could help the owners and drivers to achieve greater efficiency and output.

As well as helping to boost food production, the Irish tractor tour was also an opportunity for Ferguson to take a close look at the performance of a large number of tractors of different makes pulling various implements attached by a chain or a rigid drawbar.

Implement attachment

It was this experience that encouraged him to develop a better method of implement attachment and control, and he spent much of his time during the 1920s working with a small team from his car business to develop ideas that eventually became the Ferguson System.

By 1931 he had established the essential features of his three-point linkage with hydraulic draft control, and he was ready to form a partnership with a manufacturer who would build a tractor designed for the linkage.

The partnership idea attracted some interest, but failed to produce the agreement Ferguson wanted. He realised that one of the problems was not having a tractor that could demonstrate the practical benefits of his attachment system to a potential manufacturer.

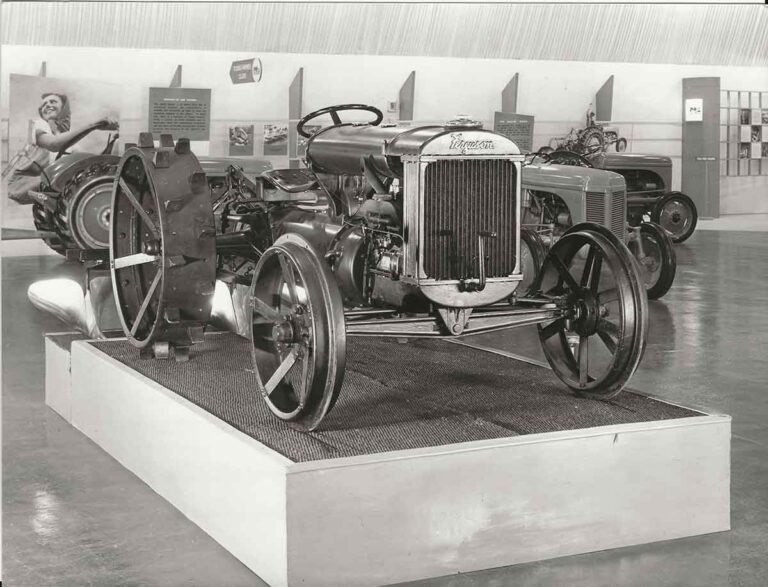

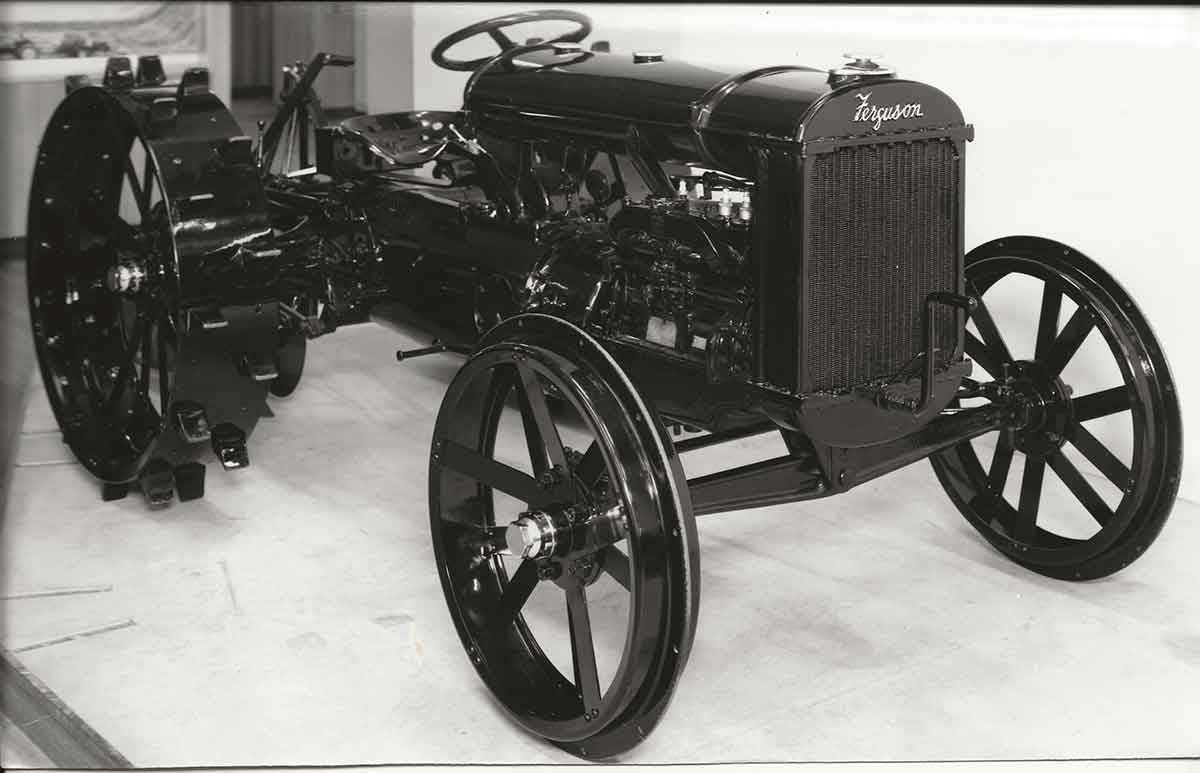

It was for this reason that the Black Tractor was built, and it was ready for use in 1933.

Design

Harry Ferguson had firmly held views on almost every aspect of tractor design, and these are evident on the Black Tractor.

The name refers to the glossy paint finish he chose at a time when the tractor industry generally was switching to brighter, more eye-catching colours, but his choice of black was probably a successful attempt to give his demonstration tractor a more distinctive appearance.

All the production tractors built under his control were finished in battleship grey. The Black Tractor design was also a result of Ferguson’s preference for a relatively light tractor, with the Ferguson System increasing the pulling efficiency.

He was concerned about soil damage caused by heavy tractors, and one of the important benefits of his attachment and control system was its ability to boost the pulling performance without the need for adding extra weight to achieve efficient traction.

Weight considerations

Ferguson was so keen to avoid excess weight that he chose a light aluminium alloy instead of steel for some of the Black Tractor castings.

The power unit chosen for the Black Tractor was an American-built Hercules IX series engine that produced about 18hp from four cylinders totalling 2,175cc capacity.

The power was delivered through a gearbox with three forward speeds and a reverse supplied by the Yorkshire-based David Brown company, a family-owned engineering business with a long history of gearbox design and production.

David Brown also supplied other components including the Black Tractor’s steering gear, and this was the start of a business relationship that soon developed into the manufacturing and marketing partnership Ferguson was seeking.

The hydraulics and three-point linkage on the Black Tractor were the latest versions of the Ferguson System and, apart from a few extra refinements, the same equipment was used on the production tractors that followed.

Ferguson System

As well as building the Black Tractor, which was assembled in Ferguson’s Belfast business premises, the Ferguson team also built a set of field machines designed to work with the Ferguson System.

As soon as the tractor was ready, it featured in a series of demonstrations to farmers and to potential manufacturing partners, attracting a generally favourable response, but it was the David Brown company that formed the partnership Harry Ferguson had hoped for and the result was the Ferguson Type A tractor, often referred to as the Ferguson-Brown, with production starting in Yorkshire in 1936.

The Type A tractor was a direct descendant of the Black Tractor.

There were some detail changes, including modifications to the Ferguson System, but the main differences were using a Coventry Climax engine for the first 250 tractors and battleship grey replaced the black paint finish.

With the David Brown partnership agreement signed, the Black Tractor had achieved its objective. Its role in introducing the Ferguson System was immensely important, and after spending the early years of its retirement as an exhibit in the Ferguson tractor museum, it was later transferred to the Science Museum in London, where it became a star attraction in the tractor section.