Telehandlers almost certainly take the most punishment on farms, perhaps even more so than tractors.

If it’s a livestock farm, it is likely being used every day to fill feeder wagons, and in a particularly difficult season it could do duty during silage-making, collecting bales or working on the clamp to produce feed.

On an arable farm, there’s grain loading, requiring some of the largest-capacity attachments on the market. This is without mentioning the day-to-day tasks that will see them used quickly to shift things out of the way.

Previously, there would have been less of a focus on the rubber that supports these machines.

However, as load capacities have continued to increase, and the cost of machinery – not to mention replacement boots – has risen, users are paying more attention than ever to ensure they have the right tyres fitted to maximise the machine’s working life.

This has coincided with greater levels of diversification within farming and contracting businesses.

Whereas previously telehandlers would have been used in yards and occasionally in the field, they are now finding their place in more industrial-style operations such as anaerobic digesters or in large-scale farming businesses, handling thousands of tonnes of material each year.

With this comes the requirement for greater versatility. These tyres should be able to handle roadwork to move between sites, deal with the rigours of loading muck in the field, and then comfortably transition to working on hardstanding.

There are also more brands than ever available in the UK, which means that whether you are specifying boots on a new telehandler or looking at the replacement market, telehandler tyres require a serious amount of consideration.

Apollo Vredestein

Recent updates to the Apollo material handling range include five new sizes in its Terra Pro series. All models feature a steel belt construction and a tie bar, offering additional stability during loading and lifting, while the sidewall protector and the resistant compound minimises the risk of cuts and cracks during operation.

The Terra Pro 1044 is designed for field work, with a tread pattern more in line with traditional agricultural tyres. Down the centre of the tyre, the lug curves off into a V-shape to always keep rubber on the ground and improve stability. The Terra Pro 1045 has a symmetrical tread pattern, made up of alternating hexagons to provide stability in all directions, even on slopes.

The new sizes are 340/80 R20 and 500/70 R24 in the Terra Pro 1044, and 365/80 R20, 405/70 R24 and 500/70 R24 in the Terra Pro 1045.

Ascenso

Indian manufacturer Ascenso says operators require three things from their telehandler tyres: load-carrying capacity, strength and damage resistance, and notes that the gap between premium and mid-level brands is closing.

It offers two ranges of radial tyres in this sector, starting with the MIR 220 steel-belted model, with a standard agricultural lug design that curves up in the middle for good performance in the field and on hardstanding. This is available in eight sizes to suit customer requirements, fitting wheel rims from 18in to 28in.

Complementing this is the MIR 221 with a block-type central tread pattern, breaking out into segmented lugs towards the shoulders. Once again, the construction comprises a steel belt and enhanced carcass for stability and load carrying. The MIR 221 is available in five sizes for rims from 18in to 28in.

BKT

BKT claims to have one of the widest telehandler tyre portfolios on the market, with several variants of its MultiMax radial range available.

The MP 525 has an all-steel construction, with a wide, non-directional tread to achieve traction in a

diverse range of conditions. Notably, the reinforced sidewall is said to provide excellent lateral stability when lifting loads.

It is joined by the MP 527, which has a block tread pattern for work primarily on hardstanding. It retains the reinforced sidewall and includes a specially developed compound for cut and tear resistance.

There is also the MP 522, which BKT says offers excellent traction and puncture resistance, making the tyre ideal for digging and loading operations.

Finally, the company offers the Con Star range, with a more traditional agricultural lug and high levels of stability for intense loading operations. Its lug design reportedly protects against lateral slippage, even

when the telehandler is

fully loaded.

CEAT

Key features of the CEAT LoadPro range include reinforced sidewalls, with layers of material adding to the tyre’s strength. According to the company, this provides lateral stability to maintain better control and handling, particularly when working on uneven terrain.

Adding to this is the lug overlap and the number of lugs, which spread the load across the full surface of the tyre. Looking at the construction, the LoadPro has a strong bead design to maintain alignment and minimise the risk of deformation or slippage when under heavy loads. It also has a steel belt beneath the tread area to protect against punctures.

For customers working primarily on hard surfaces, the LoadPro is also available with a block pattern tread.

However, this model also retains several features for work in the field, including a high tread depth and sharp shoulders for grip.

Continental

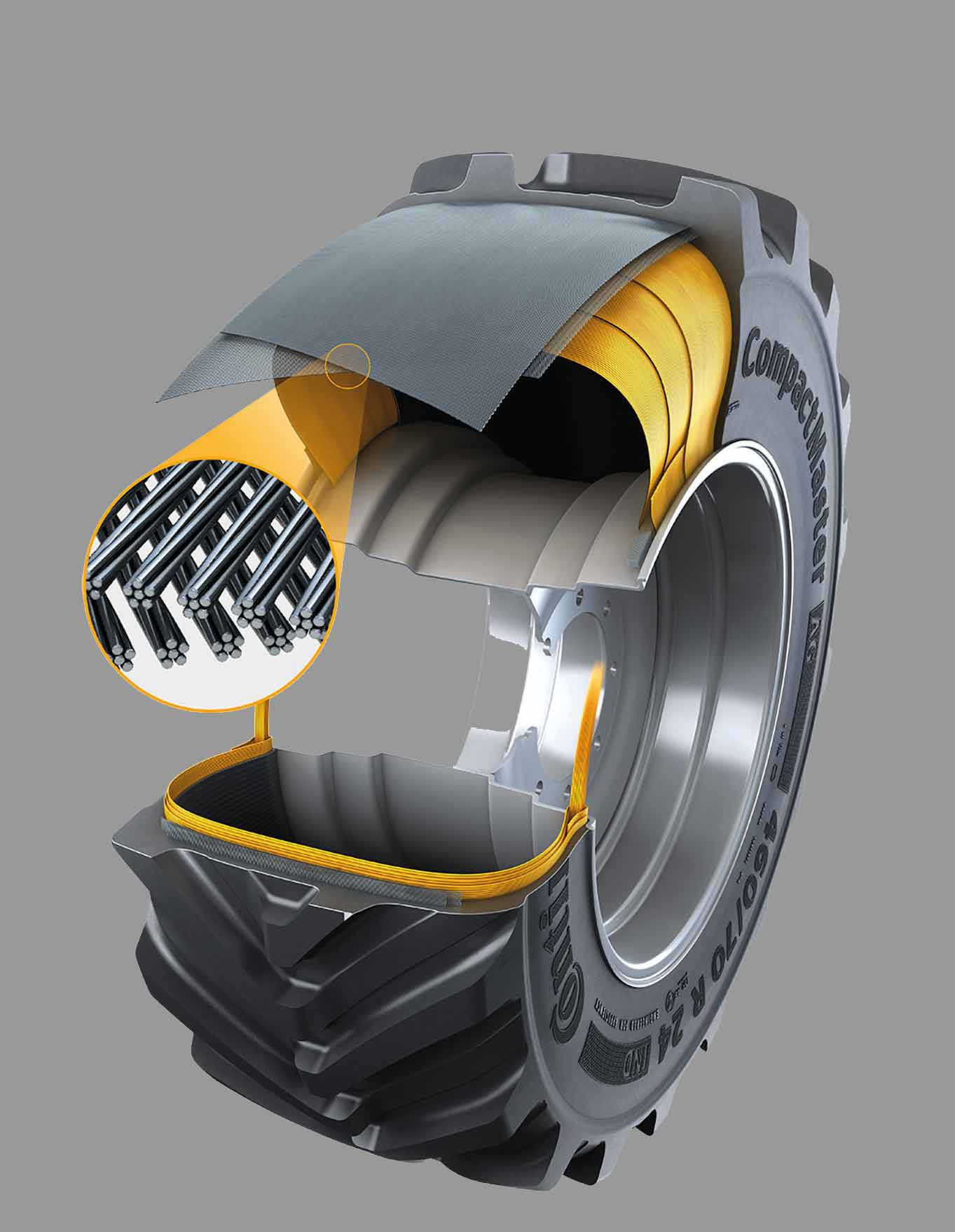

Available in two sizes (460/70 and 500/70) for 24in rims, the CompactMaster AG range features the Turtle Shield tread layer, applied just beneath the rubber, which can minimise the risk of cuts and punctures and protects the shoulder area from damage.

It also has a twisted steel belt which makes the tyre robust to handle high load capacities and stationary turns, while providing flexibility to run at lower pressures.

Continental says the tread design, while similar to a traditional agricultural layout, offers a favourable land-sea ratio of 30%, meaning a larger proportion of the rubber stays in contact with the ground.

The company also offers the CompactMaster in an EM specification for operations on hardstanding. This features a block tread pattern, keeping a high volume of rubber in contact with the ground at any one time and enabling the machine to turn on the spot.

Like the AG variant, it also comprises the Turtle Shield layer and the twisted steel belt construction.

Firestone

Firestone offers two telehandler ranges, starting with the R8000 Utility. This features a rounded lug angle to keep wear to a minimum while retaining traction on soft ground. It has a robust casing to deal with high loads and can be operated at pressures between 1.2bar and 5bar.

The sidewalls are reinforced to protect from external impacts and the tread construction comprises a minimum of six layers of rubber to stop cuts and punctures.

For work on hardstanding, the Duraforce Utility has a block tread pattern to always keep the tyre in contact with the road.

Much like the R8000, it has a robust casing with an anti-wear compound and can be operated at a range of pressures to suit.

The company adds that lateral stability is ensured due to the extra-large tread arch and the thick sidewalls. It says this design helps with precise control of the telehandler, even during complex manoeuvres.