Each method of applying slurry comes with its own limitations. For self-propelled machines and tankers, there is the issue of running heavy equipment over the soil, as well as logistical problems as these machines empty quickly and running back and forth to the yard results in a lot of wasted time.

Nurse tanks are a possible solution, but require additional staffing and can result in more equipment running over the land.

In the right circumstances, umbilical applications can eliminate many of these issues. The weight of the tractor and applicator is far less than that of a tanker, which means the window for operation is extended.

The size of the applicator is also only limited by the tractor size, rather than having to be matched to the tanker rear linkage and the overall power available.

There are also no capacity limits, with slurry pumped directly from the store to the applicator, meaning that with enough ground to cover, the operator can work consistently until the store is emptied.

There are logistical issues, of course. Umbilical works really well on ringfenced farmland, with tracks running straight from the store to the field. When you need to run pipe over roads, through hedgerows or across ditches, the operation becomes significantly more complicated.

There are options to limit the effect of this, but the long-term benefits of more permanent piping routes must be balanced against the higher costs in the short term.

Pumping options

There is a wide range of tractor- and engine-driven pumps on the market. Mastek offers the Chior tractor-driven unit, designed to handle lumpy and fibrous materials with up to 12% solids.

This is thanks to its integrated chopping unit, with a series of fixed knives, helicoid and impeller blades, all of which are manufactured using hardened materials.

To keep maintenance to a minimum, it is possible to see oil levels from the outside of the pump, and Mastek has designed the unit to keep slurry away from the gearbox, with the wet end of the pump kept well away.

It also offers the Combi Pump unit, which incorporates a PTO-driven compressor. As with the Chior unit, the Combi Pump can handle up to 12% of solids within the slurry.

It also features a hydraulic clutch for easy switchover between the pump and the compressor unit. The compressor can operate at up to 10bar and is reportedly capable of blowing out up to 3km of piping.

Standalone pumps

Tramspread recommends standalone engine-driven pumps, which the company states will use up to 35% less fuel than a comparative tractor-driven model.

These are offered either as skid-mounted or trailed units, with options to add a compressor unit.

Tramspread also developed the Contractor Trailer – using the company’s own experience as slurry contractors. These self-contained units feature an engine-driven pump unit, compressor, capacity for 2,000m of hose and storage for oil, tools and couplings.

The typical specification of this includes a 175hp FPT engine, with the option to increase it to 238hp; a Bauer SX2000 pump (with the option to swap it for a Doda or Cri-Man model); a Bauer vacuum pump for priming; multiple options for compressors; and a 900-litre fuel tank.

All of this is mounted on a twin-axle trailer with suspension and airbrakes.

A comprehensive range is also offered by Storth, with both the Bauer Magnum SX and Doda AFI chopper pumps available.

The Bauer range has a four-blade impellor, spinning at 2,600rpm, with the wet end separated from the gearbox. These are suitable for tractors between 130hp and 195hp, with possible outputs reaching 305cu m/hour.

The Doda models use an eight-blade impellor and separate the gearbox from the slurry, but have no dry running capacity.

Looking at the HD variants, this includes an oil cooling jacket, which uses the passing slurry to help cool the gearbox oil on long pumping days. The HD models have a starting requirement of 170hp, with a maximum output of 300cu m.

These pump units can also be integrated into an engine pump station from Storth, reducing the number of tractors required, and is said to fully realise the pumping potential of the Bauer or Doda. Engines of 175hp or 238hp are available, with either a 650-litre or 1,000-litre fuel tank.

The Wox Agri Services pump units – offered as the Invader trailer-mounted, engine-driven or the Walrus (either engine or tractor-driven) – are said to avoid any priming or dry running issues, thanks to the charged pump being mounted at the end of a 9m arm.

Each unit includes an integrated jetter, which helps to mix the slurry and create a homogenous, flowing material.

As standard, Cornell pumps are used in the Wox range, with other brands available on request.

Bauer and Doda pumps are the centrepiece of the Spreadwise engine-driven pump range, with the option to have a Ferrari unit. Each pump station is built bespoke to the customer’s needs, but is said to offer lower fuel consumption, reduced operating costs and an increase in productivity.

Remote control

When it comes to pump control, Storth offers the FarmerPlus basic control panel, mounted on the pump and providing a rev counter, hour meter and warnings for low oil pressure or excessive water pressure. This comes with a manual throttle and slurry feed control.

More advanced is the company’s ContractorPlus remote-control system, with a 7in screen providing a live feed of the pump unit.

It offers a range of up to 5km, depending on environmental factors, and provides access to automatic headland management, flow meters, pressure monitor and control of the compressor.

Offered alongside its Contractor Trailer and pump units, Tramspread provides a range of remote control options, starting with a GSM system, the Teletram 2020, radio-controlled units and the SIL Vision IV.

The pump can be controlled from the tractor cab, and with sensors on the inlets and outlets, it is possible to monitor the flow of slurry for hose leaks.

Drag hose and reelers

Once the slurry has been pumped out of the store, it needs to get to the applicator. Unreeling the drag hose and then packing it away after a field is completed can be a time-consuming operation, so the capacity and ease of use become key selling points.

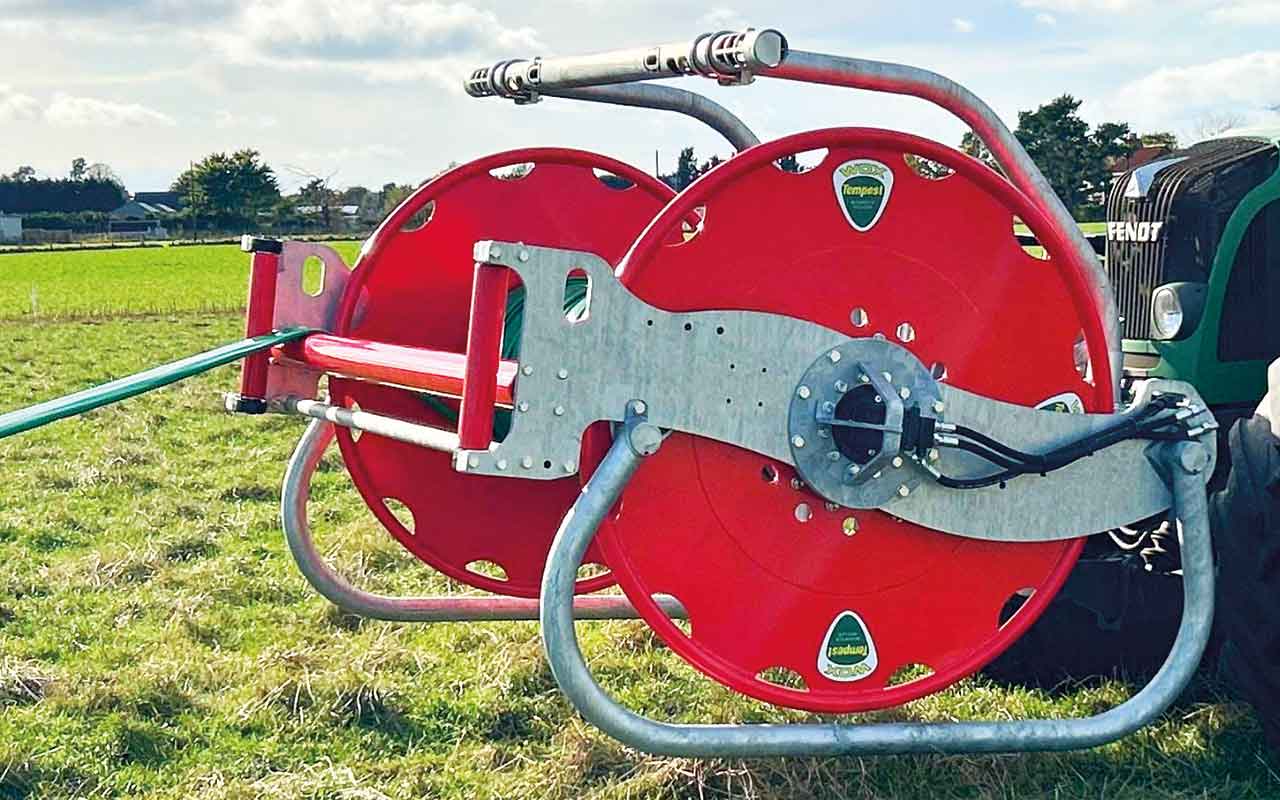

Wox offers three different models of reeler, with the mounted Tempest and Scorpion units capable of carrying up to 1,200m of 6in piping.

The trailed Tempest model significantly increases this capacity, with up to 3,000m of 6in hose being carried. The company uses Metal 360 couplings, alongside Gollmer & Hummel hoses.

The use of unisex couplings enables the hose to be reeled in from either end, with the models used by Wox having a short length to maximise the reeler space.

The latest drag hose from Tramspread is the Gollmer & Hummel RIB PU blue ribbed, which has polyurethane through-the-weave extrusion for protection against damage.

The company also offers a full range of Mandals hose, as well as reelers to hold 600m, 1,000m or 1,400m. The larger units use a twin hydraulic motor driveline.

Additional products include a drag loop to move the hose across tramlines, as well as a Wagtail hose humper, which has a hydraulically controlled wheel and hose pinchers to avoid spillages during turning.

Storth’s reeler range runs up to a 2,000m trailed model, which is offered galvanised, with hydraulic drive and LED lighting, mounted on a heavy-duty chassis.

The top specification is the ContractorPlus model, which adds a hydraulic steering drawbar to aid entering gateways. Storth reelers are set up for 4in or 5in hose as standard, with 6in and above available on request.

Finally, Mastek’s Auto Reel tops out at 1,200m, with 600m, 800m and 1,000m options also available. It includes an automatic hose guide which keeps piping evenly distributed across the reel, and is driven directly by the hydraulic spool, eliminating the need for additional connections.