EIMA International, which took place from 6-10 November in Bologna, Italy, provides an opportunity to not only see the headline-making, flagship machines, but also turn our attention to more specialist equipment. Its Italian base means it is a hotbed for viticulture and specialist equipment.

This year it hosted more than 1,700 exhibitors and saw 346,800 visitors, both from within Italy and further afield.

Alongside the event, the EIMA Technical Innovation Awards always have some interesting products. Held since 1986, the competition has honoured the latest in technological solutions for the agricultural industry.

An international panel assesses each of the entries, covering a broad spectrum of tractors, implements and components, before handing out the awards.

A total of 68 products were recognised for their innovation. Twenty received medals, with another 48 receiving honourable mentions. Below we have highlighted select innovations from key manufacturers.

Agrinova

A novelty for the groundcare and forestry markets, Agrinova was given a special mention for its Kolisfera hybrid tracked woodchipper. It features an electronic-injection, 14hp petrol engine, linked to an electric transmission, which can be moved in either electric or hybrid mode.

Capable of shredding wood up to 10cm in diameter, the rotor is fitted with three hardened blades, with the ability to open the hopper for easy inspection and maintenance of wearing parts. To suit the environment, the discharge height can also be reduced. Functions are controlled via a 2.8in colour display, with backlit keys.

Alpego

Italian manufacturer Alpego, now distributed across the UK by Opico, received a medal for its 3m Alysium electric rotary harrow. Power from a 700V DC power connection from the tractor is transferred to five electric motors, which actuate an individual input gear.

Each of the rotors are connected by a series of gears, like a traditional harrow, but the company states that the electronic control will enable the machine to work within user-defined parameters.

It also provides a system that can be built upon in the future, with the possibility to integrate real-time adaption to soil conditions.

Case IH

The potential productivity benefits of the newly developed suspension system on Case IH’s flagship Quadtrac machines were highlighted at the awards.

Designed from the ground up, the mechanical system is hydraulically cushioned, with independently suspended idler and mid-roller wheels.

According to the company, the setup provides a 42% reduction in vertical movement at the cabin. The diameter of the drive wheel has been increased by 11% and the tracks have been lengthened by 5%, ensuring a longer track life while also increasing traction, minimising ground pressure and reducing smearing.

For easier maintenance, the track units require no grease and have no sensors or wiring, as well as featuring automatic track tensioning and maintenance-free bushes and pins.

Dieci

Developed to simplify the changeover of implements on telehandlers, Dieci’s Fast Attach system allows the mechanical, hydraulic and electrical connections to be completed in a single movement, without the operator having to leave the cabin.

The operation is fully controlled using an in-cab interface. According to the company, coupling and uncoupling can be done in as little as 10 seconds, with a reduction in possible hydraulic leaks as the system is enclosed.

Notably, this system can be retrofitted to existing Dieci telehandlers, which means customers can take advantage of Fast Attach without having to invest in a new machine.

Kubota

Building on the existing Tractor Implement Management (TIM) system, Kubota’s TIM Pack 2.0 has been integrated into its BV6160-6190 round baler range.

Updates include the ability to control the hydraulic swinging drawbar based on feedback from the intake sensors. This adjusts the baler to the left or right to automatically adjust the intake and maintain the maximum capacity.

Auto Blockage Control and Monitoring has also been implemented, reportedly reacting quicker than a human could to avoid blockages completely stopping the crop flow. When a blockage is detected, the parallelogram drop floor is automatically released so the blockage can pass.

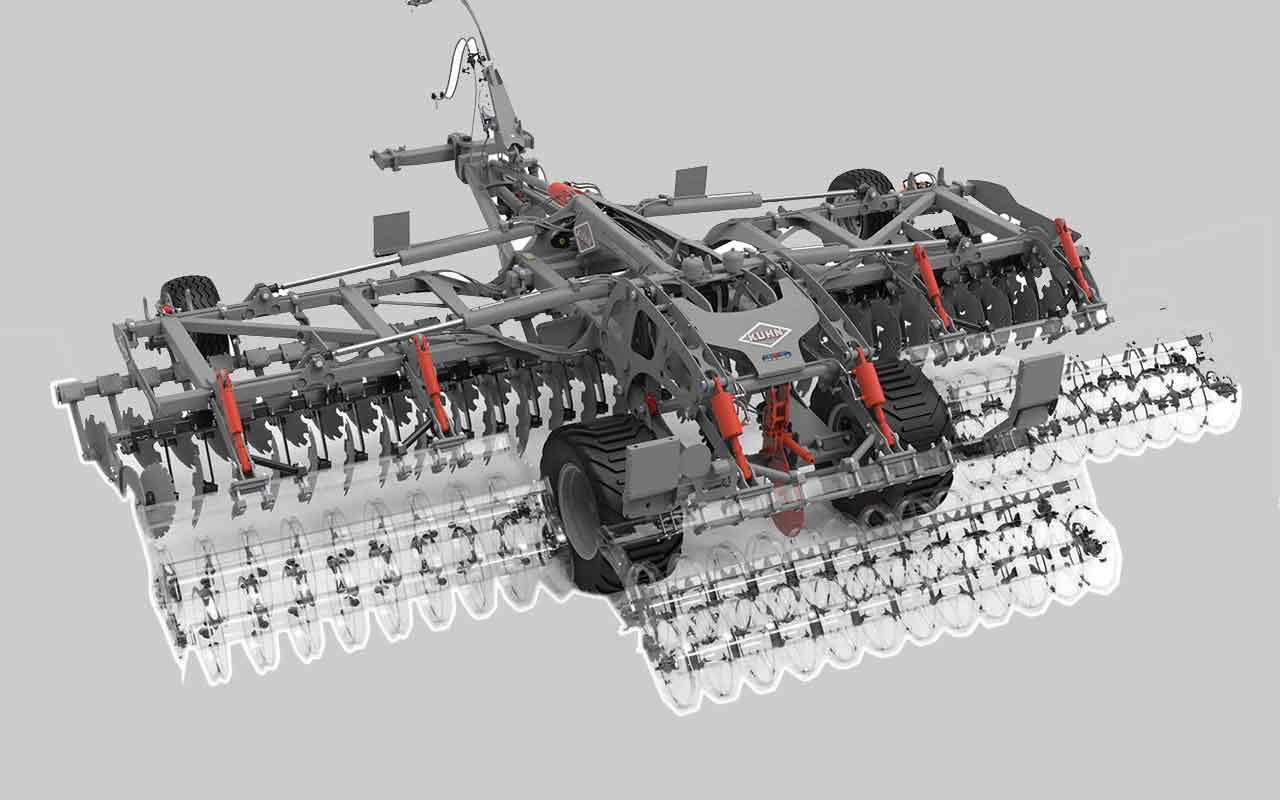

Kuhn Farm Machinery

Kuhn’s Smart Soil Technology has been integrated into the Optimer 6m and 7.5m machines. The Isobus system enables all functions to be controlled from the cabin, with automated features to enable the cultivator to adapt to soil conditions.

Steady Control Ultimate uses pressure and position sensors to adjust the extension cylinders and maintain the correct working depth, regardless of undulations and forward speed. Auto-Line automatically corrects the alignment to ensure that the machine works in line with the tractor, adjusting the gauge wheels and roller to balance lateral forces.

Finally, the Isobus task controller includes section control to automatically lift the machine out of work at the headland and lower it back into work at the next pass.

Kuhn Farm Machinery

Kuhn received a second medal for the integration of Tractor Implement Management (TIM) into its VB 7100 variable-chamber balers.

With this, the company has reportedly created the first balers to include section control, with the pick-up automatically lifting and lowering to reduce machine wear and improve operator comfort.

TIM also enables the baler to automatically bring the tractor to a stop when the bale chamber is full, as well as eject the bale once the net has been applied. The tractor is also stopped when a blockage is detected, with automatic deblocking of the machine, and the knife is cleaned without operator intervention.

Landini

Fitted to the Tractor of the Year 2024 Best of Specialised winner, the Rex4, Landini’s Rex4 Energy system received a special mention in the awards.

It comprises a generator under the bonnet which powers an electrical socket at the rear of the machine. This can be used to supply 10kW, 48V, to implements such as electric mistblowers, enabling the implements to work effectively while the tractor remains at a low engine speed.

A further advantage, according to the company, is the removal of the PTO shaft, which enables the machine to make tighter turns at the headland, and also improves health and safety when hooking up implements.

Manitou

Receiving a special mention at the awards, the Manitou Smart Weighing System is available as a factory-fit option or as a retrofittable system. It is a fully integrated weighing system that continuously monitors the load, offering both dynamic and static figures regardless of the boom position.

Data is shared to both the in-cab dashboard – avoiding the need for an extra screen – and the MyManitou app, with the app providing geolocalised information for storage management. When loading a feeder wagon, operators can be sure to add exact amounts of ingredients to reduce wastage.

Merlo

First presented as a prototype at Agritechnica, the Merlo TFe43.7 is a medium-capacity telehandler, equivalent to the company’s TurboFarmer range, and the latest model to be powered by batteries.

It has a 7m maximum reach, a lift capacity of 4.3t and can be put to work in enclosed areas or on construction sites thanks to zero tailpipe emissions and significantly reduced noise pollution.

According to the company, it has a possible autonomy of eight hours and can reach 33kph on the road. It joins the established e-Worker 25.5 in Merlo’s electric telehandler portfolio.

McCormick

Taking home a fourth consecutive award, McCormick has developed the Hyper Safety View system, comprising four cameras (three on the roof and one on the front of the bonnet) to create an automotive-style, 360deg view around the machine.

Camera feeds are displayed through the DSM screen in the cabin, with five visual modes available.

Polar View uses radar to identify the distance to any obstacles, Surround gives a 360deg top-down view, AR shows the trajectory of the machine over the real-time camera feed, Camera enables zooming in on an image, and ADAS gives extra visual support for connecting implements.

New Holland

Designed for specialist tractors, New Holland was awarded a medal for its integrated Lidar vision guidance technology. Developed to work in place of a GPS signal, the system can handle in-row guidance, headland turns and implement control.

As it uses Lidar, accuracy is not affected by a loss of signal, and tractors equipped with the system can be used in areas with canopy coverage, netting over the crop or in valleys and glasshouses.

At the end of the row, the system can automatically decide on the best headland route to the next pass, with different turning options available. A collision check mechanism also informs the operator if a turn cannot be completed.

New Holland

EIMA technical innovation mentions were also given to the New Holland CR Twin Rotor combine Seed Terminator systems. The system can be integrated into the CR8.90/9.90 rotors and was developed by the Australian firm of the same name.

It uses multi-stage hammer mills on a barrel housing to kill weed seeds coming from the cleaning shoe and eliminate their ability to germinate on the ground.

Thanks to this feature, farmers get a new opportunity to kill weed seeds during the harvesting process, reducing the use of herbicides and improving the capacity to fight against resistant weed seeds.