The wind represents a significant issue for operators trying to maintain an even fertiliser spread pattern and Amazone offers WindControl, a system that continuously monitors the effect of wind and automatically compensates. Previously this has only been available alongside the ArgusTwin spread fan monitoring system but Amazone is now making it available as an independent option on ZA-TS mounted and ZG-TS trailed machines.

How the wind impacts the spread pattern is constantly changing, with strong or light winds, different wind directions and sudden gusts all having an effect. Headwinds and tailwinds stretch or compress the spread pattern, without impacting the lateral distribution, while crosswinds impact the working width considerably. This is compounded by the fact that most fertiliser applications take place in the spring when the probability of working in windy conditions is particularly high. The WindControl system is tasked with restoring the symmetrical spread pattern when windy conditions have an effect.

A high-frequency wind sensor mounted on the spreader records both the wind speed and direction and transmits this to the job computer, which then processes the data with the current forward speed and calculates new settings for both the delivery system and spreading disc speed. These are then automatically adjusted.

If there is a crosswind, the disc speed on the side facing the wind is increased and the delivery system rotated outwards. At the same, the speed of the downwind side is reduced and the delivery system rotated inwards to counteract the wind effect and ensure accurate distribution. One key benefit, according to Amazone, is that WindControl results in larger working windows for fertiliser application.

In addition to this, the operator always has an overview of the current wind situation, including direction, strength and gustiness in the work menu. Traffic light colours are used to signal the extent to which the WindControl system is able to compensate for the effect of the wind, and a warning is issued when the limit of the system’s control is reached.

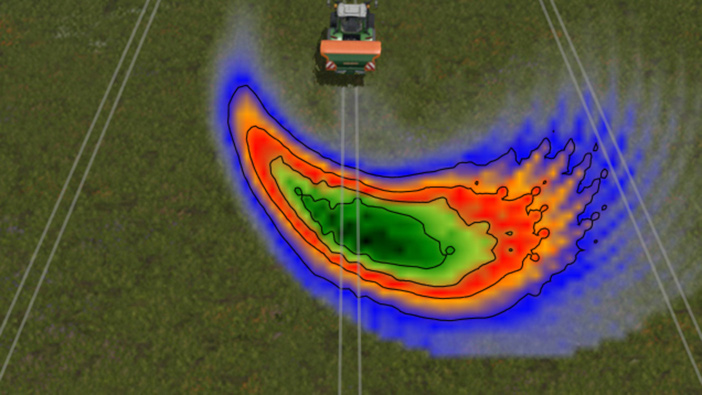

Without WindControl: Crosswinds affect the distribution pattern and change the lateral distribution.

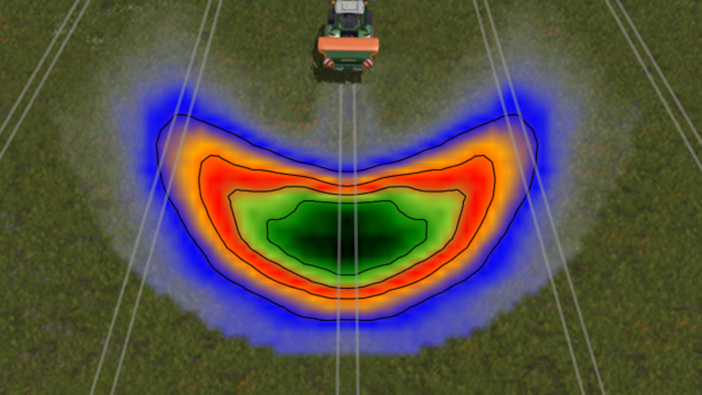

With WindControl: WindControl counteracts crosswinds ensuring an optimum spread pattern at all times.

The mast holding the sensor automatically extends when the spreading discs are activated and protrudes above the cab so as not to measure any turbulence generated by the tractor. When the discs are switched off, the mast retracts to the protected position between the tractor and spreader. It is also possible to operate this manually if preferred.

The ArgusTwin system is still available in addition to WindControl, which allows the spread pattern from both the right and left discs to be constantly monitored by 14 radar sensors. If any deviations, the lateral distribution is automatically optimised by adjusting the electronic delivery system and this can be carried out individually for each side for the best lateral distribution. The company states that ArgusTwin is particularly useful when spreading on slopes, using non-homogeneous spreading materials or when moisture has an impact on the operation.

For more information go to www.amazone.co.uk