Pöttinger has completed the second phase of expansion at the Technology and Innovation Centre (TIZ), with the new hall now fully operational.

The centre was founded in 2002, with the manufacturer being one of the main tenants. Its test centre is designed for prototype construction, testing, measurement and inspection, extending beyond Pöttinger’s portfolio to run pilot projects for third parties.

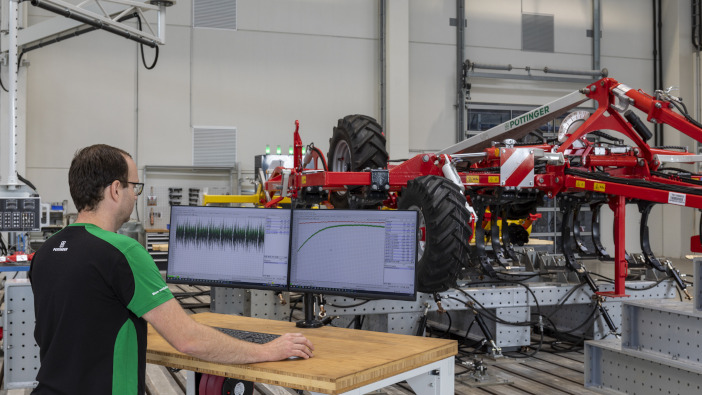

The new building increases capacity, offering 1,800m2 of additional floor space. Of this, 1,300m2 is dedicated to testing technology, with the rest used for prototype development. Equipment includes a 360m2 component testing station.

Testing cylinders are powered by a 400kW hydraulic unit, while two ten-tonne cranes are fitted to move fully constructed machines onto the testbed.

The extension also adds a workload testbed, allowing the company to run a comprehensive analysis of completed machines, as well as the capacity to test scenarios with electric equipment.

Markus Baldinger, Pöttinger managing director said: “In addition to investing in our modern production plants, we have a strong focus on the possibilities for testing and inspecting our agricultural machinery. This additional investment in TIZ 3 sees us fulfilling our promise to our customers regarding high quality, strength, reliability and durability.”

According to the company, the tests that simulate real operating conditions save up to 75% of the time and costs compared to practical tests performed in the field.

“Our technology stands for the best working results. We aim to deliver the highest quality, reliability and durability. With the additional hall and the latest technology, we can offer our customers even more. Now that we can perform e-mobility testing, we are right up to date in attracting new companies through TIZ Landl GmbH,” Mr Baldinger concluded.

For more information go to www.pottinger.uk