Dunmore Hind, who farms 800 hectares in Lincolnshire with his father Alan, invested in a new Mecmar S 40 T mobile drier before harvest 2023. The family, which farms under J Hind and Son, aim to combine milling wheat as quickly as possible, regardless of moisture content, to maintain the quality, meaning that the catchy weather conditions this year led to a baptism of fire for the new machine.

“We probably cut the first 2,000t of our milling wheat at between 18-20%, and before that, we had cut 400t of oats at 19%. So for 14 days, the Mecmar ran constantly,” explained Dunmore.

The new drier was supplied by Sharmans of Stamford and installed by McArthur Agriculture. It represented the second stage of the family’s plans to upgrade their grain processing capabilities. “Tom Barker from Sharmans knew that we were looking to make changes to our grain drying and storage facilities and suggested that we talk to the McArthur Agriculture team to work with us on Phase 1 of the development.”

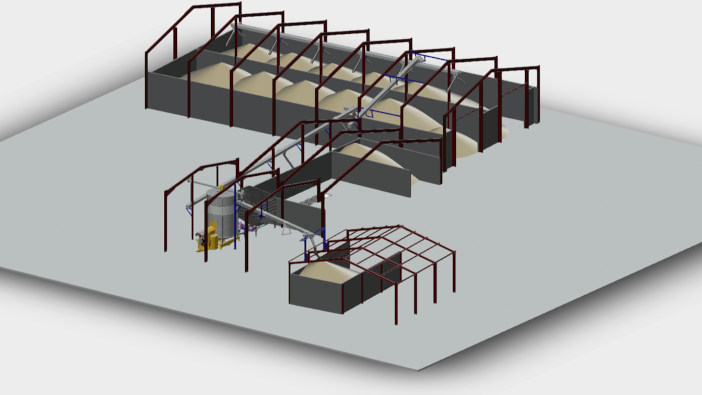

After a site visit, McArthur designed a system incorporating the family’s old drier, fed by a 12m Skandia Elevator 60 tonnes per hour I-Line trench intake. The intake was designed with prefabricated components, concrete troughs and prefabricated grids to make the installation as easy as possible.

An existing hopper was retained and from the drier, grain is transported via three 120 tonnes per hour I-Line conveyors to a 3,000-tonne store. The design also included a small building to house the existing drier and future-proof the design for further development.

The system worked well in 2022 but for 2023 the acreage of milling wheat was increased, putting more pressure on harvesting times.

“We realised that we needed to invest in a bigger drier. Following further discussions with McArthur around Phase 2, we purchased a Mecmar S 40 T which was installed together with an additional conveyor giving us additional flexibility to store grain in another shed, in time for harvest 2023,” said Dunmore.

They opted for the latest automation control system, with a touchscreen and remote access. This also communicates with a new Mecmar grain moisture probe to ensure that unloading only happens when the grain is cool and dry.

If the reading is outside of the predefined settings, then an alert is sent to the operator who is able to control whether grain should be discharged or if it needs further drying. “The new grain moisture probe is a double-check as it uses the temperature of the grain which is then validated by the measurement of the mc. This helps to ensure that grain continuously goes into storage at the optimum moisture,” said Dunmore.

“Apart from having to stop the drier to check belt tensions, receiving an alert on my phone or seeing a flashing light on the control panel telling me that the bearings need greasing, the Mecmar just keeps working!” he concluded.

For more information go to www.mcarthuragriculture.co.uk